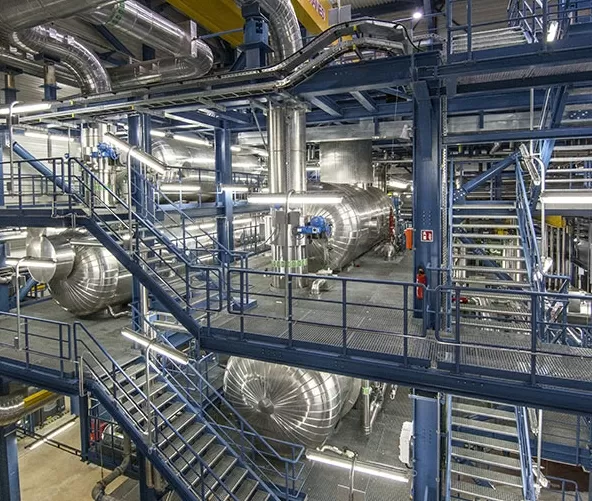

Heat exchangers for gas power plants

Learn more about our heat exchanger offerings for gas power applications, including water-cooled condensers as well as feedwater storage tanks and daereators.

Heat exchanger offerings

GE’s product portfolio covers a wide range of heat exchanger products, providing options to enhance combined-cycle power plant operation and performance. We have more than 50 years of experience in engineering, manufacturing, and commissioning heat exchangers and have developed high performance and competitive in-house thermal and mechanical engineering standards. This capability lets us act as an integrator and contributor to the enhancement of overall plant configuration and performance.

Water-cooled condensers

GE Gas Power offers high-performance deaerating surface condensers. These water-cooled condensers support a wide range of steam turbine applications—from smaller industrial scale to larger utility scale units.

Feedwater storage tanks and deaerators

Proper deaeration of HRSG feedwater/make-up water is crucial to protecting your gas power asset from harmful corrosion. GE’s feedwater storage tanks and deaerating direct-contact feedwater heaters feature simple, yet robust configurations that are based on decades of experience. These storage tanks and deaerators accommodate all combined cycle power plant applications and operate across all load ranges to provide high condensate returns and make-up water flows.

District heaters and low pressure feedwater heaters

GE’s district heaters transfer up to 300 MW of thermal heat with highly efficient heat transfer coefficients and optimum heat transfer surfaces. This type of district heater is extremely reliable, even under transient conditions, and is a major contributing factor to increasing fuel utilization. GE district heaters are of shell and tube type with tubes fixed in a tubesheet. They are designed either as a condensing heat exchanger or with an integral drain cooler zone.

Customized by GE, our low pressure feedwater heaters improve system thermodynamic efficiency by pre-heating water for the steam generating boiler. Once they are commissioned and tuned via the power plant’s control system, GE’s feedwater heaters are maintenance-free.

Shell and tube and other heat exchanger products

In addition to the above highlighted offerings, GE offers many other heat exchanger products, including shell and tube water/water coolers—applied to closed cooling water systems or district heating applications—and atmospheric drain vessels for collecting all external drains, efficiently separating water and steam.