A legacy of steam turbine experience

For more than 120 years, GE has led the industry in steam turbine technology and innovations. Today, GE’s steam turbines continue to lead the way, delivering efficiency and reliability to help ensure our customers’ success.

GE’s steam turbines equip 41% of the world’s combined-cycle plants. Right now there are more than 1,000 combined-cycle steam turbines operating in 70+ countries, generating more than 140 GW of power. Our steam turbines can be installed and operational in eight months or less for industry-leading commissioning.

Steam turbines with high availability and reliability

- Our robust, reliable steam turbines are enhanced by control systems and the power of GE Digital solutions.

- Our proprietary long-term testing program validates material behavior and improves steam turbine component reliability.

- Advanced techniques during the design phase result in lower maintenance intervals and increased turbine availability.

- Hardware is thoroughly tested to make sure every machine meets the reliability and performance standards our customers demand.

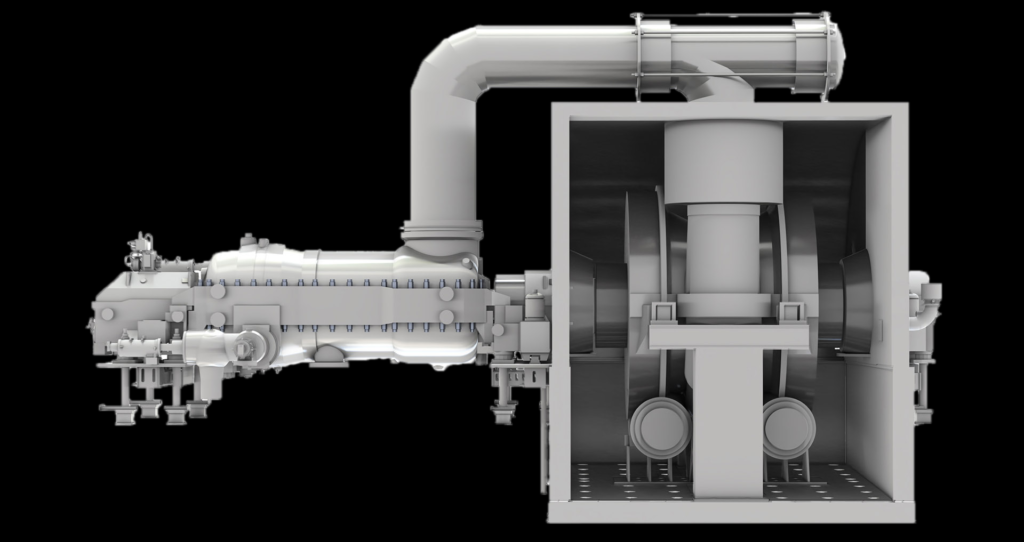

High-efficiency steam paths

- Industry-leading performance with high reaction 3-D blading designed for high pressure (HP), intermediate pressure (IP) and low pressure (LP) steam turbine modules.

- Integrally shrouded blades with continuous contacting surfaces provide excellent damping capability for superior mechanical integrity.

- Our steam turbine design process provides precise control of radial clearances and throat areas to help ensure greater output and efficiency.

- State-of-the-art technology and deep expertise are applied to our broad last stage blades portfolio for improved efficiency, reliability and availability.

Enhanced operational flexibility for steam turbines in thermal power plants

- Advanced life prediction methods provide reliable lifetime assessment of the steam turbine components and increased cycling capabilities.

- Enhanced blade-to-rotor connection design reduces thermal stresses for increased rotor life.

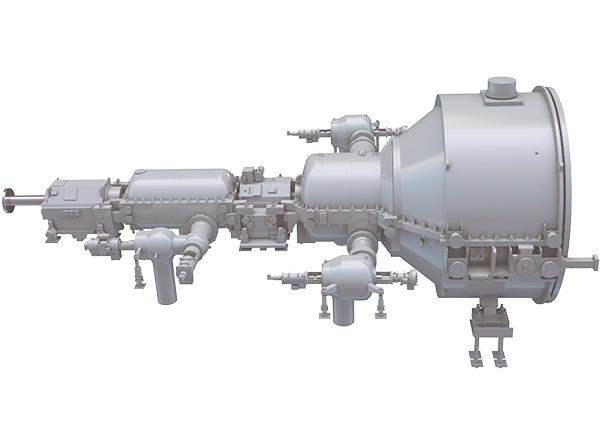

STF-600 series steam turbines

GE’s STF-A650, STF-D600, and STF-D650 combined-cycle reheat steam turbines deliver the performance, reliability and efficiency for today’s 50 Hz and 60 Hz applications.

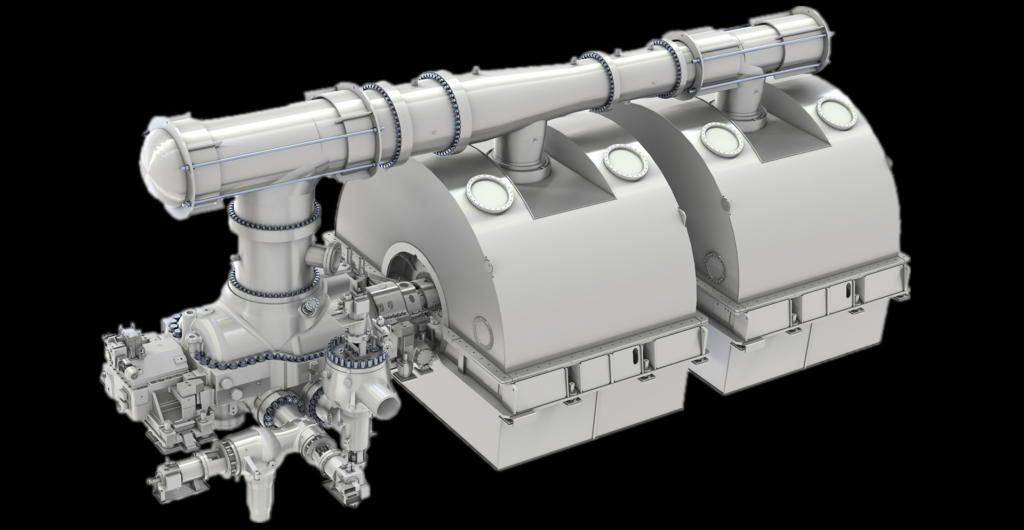

STF-200 series steam turbines

GE’s two-casing dual LP flow STF-D200 steam turbine and single-casing, axial exhaust STF-A200 steam turbine provides flexible configurations in 50 Hz and 60 Hz non-reheat applications in multi-shaft and single-shaft configurations, covering a wide range of industrial and utility applications.