Steam turbines from 10 kW to 1,900 MW

With over a century of experience and continuous development in our steam turbine technology, Siemens Energy is a prime partner for your business. More than 120,000 steam turbines delivered worldwide prove that we are a reliable and experienced partner.

Our steam turbines work as generator drives or as mechanical drives for compressors or pumps. They play a significant role in many combined cycle and cogeneration plants and in industrial applications. Steam turbines are also often applied in the renewable energy sector. Be it power generation plants, district heating, biomass, waste-to-energy, seawater desalination or solar heat: There is a wide range of applications for steam turbines made by Siemens Energy.

Utility steam turbines from 90 to 1,900 MW

Siemens offers a comprehensive range of steam turbine products in the power output range from 90 to 1,900 MW. These are used in conventional fossil-fired steam power plants as well as in nuclear and combined cycle power plants. With more than 8,000 steam turbines in service worldwide we provide proven technology, adapted to the specific local conditions.

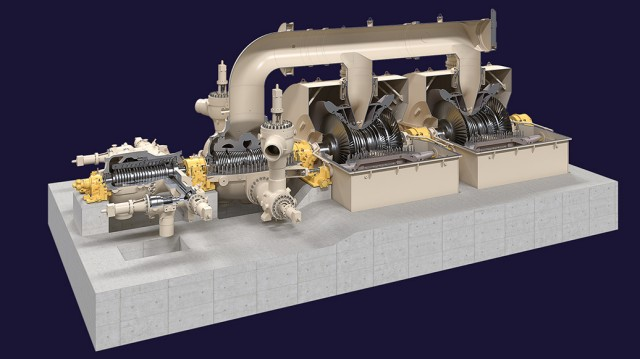

SST-3000

Flexible steam turbine for applications in single-shaft and multi-shaft combined cycle configurations

The compact arrangement features a two-cylinder design with an axial exhaust for use in combined cycle power plants.

The SST-3000 series covers the power output range from 90 to 275 MW. It features a separate high-pressure (HP) turbine and combined intermediate-pressure / low-pressure (IP / LP) turbine with single flow axial exhaust for 50 and 60 Hz applications.

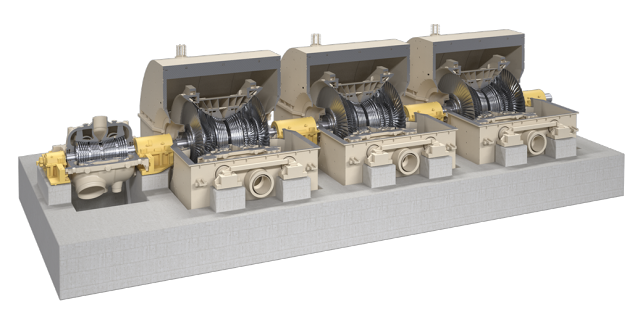

SST-4000

Powerful and reliable – thanks to proven design for high efficiency.

The SST-4000 series is our specialized turbine for non-reheat, combined cycle applications. With the specialized design of the blade path, the entire power range from 100 to 500 MW can be covered with the highest reliability and availability. More than 40 turbines of this type are already in operation or in the commissioning stage, with a total installed capacity of approximately 8,200 MW.

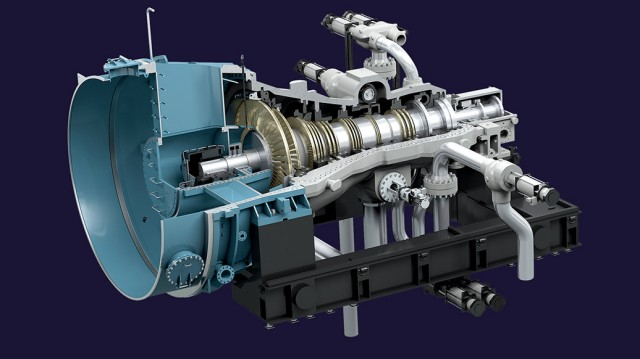

SST-5000

A steam turbine with short start-up times and variable start-up modes to ensure grid stability

Siemens Energy Steam Turbines of the SST-5000 series are operated in combined cycle power plants (CCPP) and in steam power plants (SPP).

The SST-5000 steam turbine combined with a gas turbine, is able to achieve a net plant efficiency of more than 64 percent in combined cycle applications.

SST-6000

Reduced life-cycle costs

Siemens Energy Steam Turbines of the SST-6000 series are widely operated in steam power plants with a power output up to 1,200 MW and an efficiency up to more than 46 percent.

Products of the SST-6000 series consist of a high-pressure turbine, an intermediate-pressure (IP) turbine, and up to three low-pressure turbines for 50 and 60 Hz.

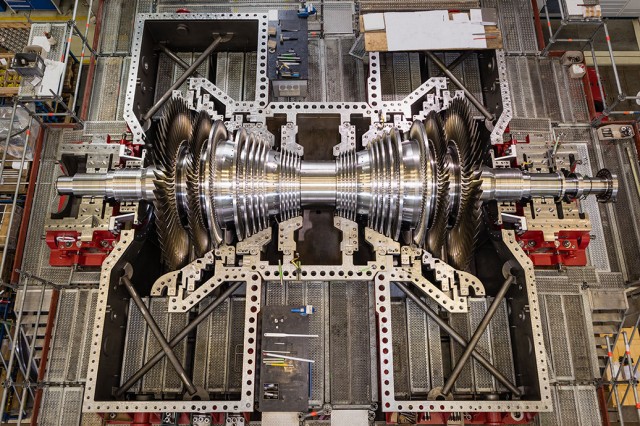

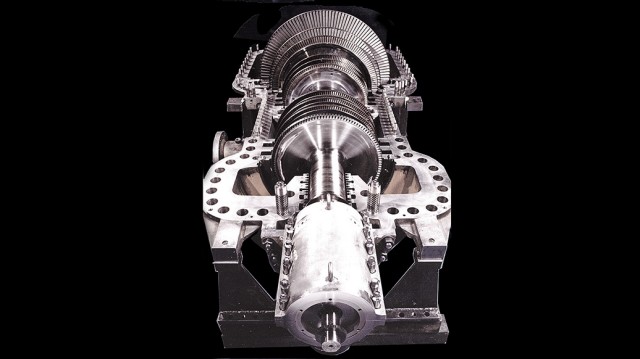

SST-9000

Leading technology for efficient, flexible and reliable power generation

Siemens Energy Steam Turbines of the SST-9000 series are highly reliable for the application in conventional islands of advanced pressurized water reactors in nuclear power plants, with a power output up to 1,900 MW.

The half-speed (25 turns per second) SST-9000 series consists of a double-flow high-pressure saturated steam turbine (HD) and up to three twin-flow low-pressure turbines (ND) with shrunk-on wheel disc rotors. Siemens low-pressure turbines with shrunk-on wheel discs represent technology that has been proven over decades. The result: no stress corrosion cracking and thus no replacement of the low-pressure rotor or wheel discs during the excepted service life.

Industrial steam turbines from 2 to 250 MW

As a market leader for industrial steam turbines, we offer a comprehensive range of reliable and versatile steam turbines for the power output range from 2 to 250 MW. Our industrial steam turbines are designed for easy constructability, fast start-up and economical operation.

SST-800

Flexible condensing or back-pressure steam turbine.

We deliver a standard steam turbine generator set including the SST-600 (with or without gearbox), a generator, oil system, piping and instrumentation and the control system. The standard package can be extended to include a condenser, condensing plant or pre-heating system. The SST-600 with its reliable and flexible design is available with axial or radial exhaust.

Mechanical Drive

The SST-600 is also an efficient and economic mechanical drive. Since the 1970s, hundreds of projects have been successfully implemented all over the world using the SST-600 to directly drive everything from the smallest boiler feedwater pump just as reliably as the largest compressor even in the most complex processes. The SST-600 complies with regulations including the API standard.

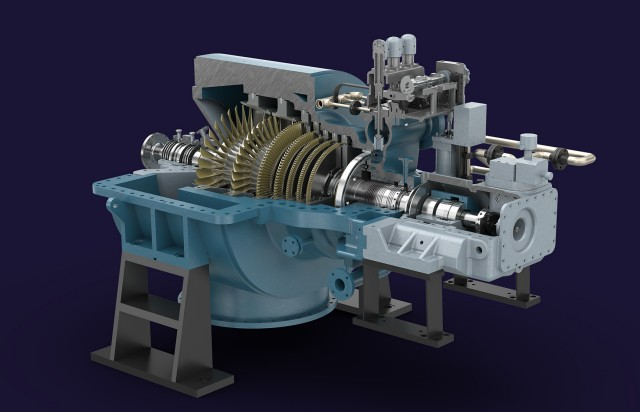

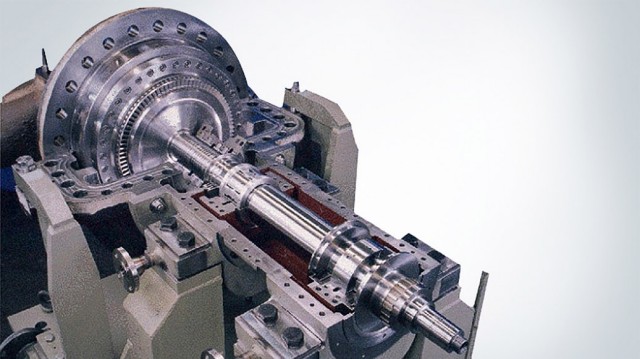

SST-500

Double exhaust flow steam turbine

The SST-500 is a single casing, double exhaust flow steam turbine, which can be used as an entire drive or as the lowpressure module of a multiple-casing turboset, directly driven or geared. This turbine, with its capacity to operate over a wide range of speed and power, is ideal for large steam volume flows. Steam flows into the turbine via two tangential inlets to equalize thermal loading and blade stress.

Emergency stop valves and control valves are installed in the steam inlet pipes. The steam flows tangentially into the inner casing and then axially to both exhausts. The customized design of the steam path allows exact adjustment to surpass general physical limitations of the last stage blades. Double-end drive is available, if required, e.g. for booster pump drive.

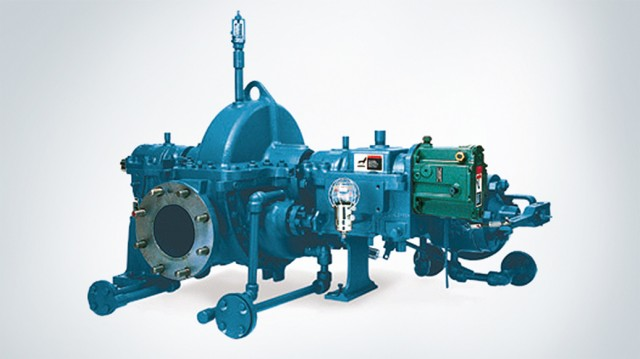

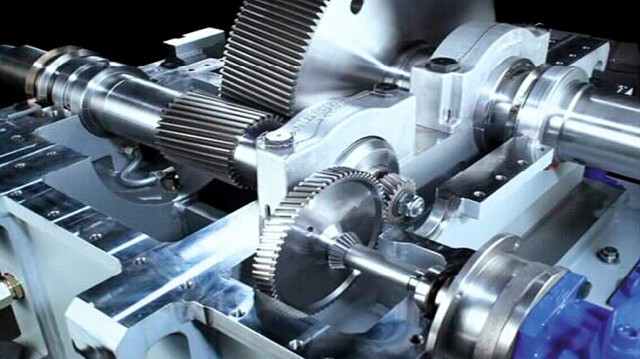

SST-400

Industrial steam turbine

The SST-400 is a single casing steam turbine, providing geared or direct drive to 50 and 60 Hz generators, or to compressors and pumps. The symmetrical casing with horizontal joint flange enables the SST-400 to accept short start-up times and rapid load changes.

The modular package design allows a wide variety of configurations to satisfy the customer’s individual needs in the most economical way. The utilization of selected proven components assures high reliability and easy maintenance.

The SST-400 can be equipped with upward, downward or axial exhaust to fit with the selected installation. The turbine skid can be combined with standardized gearbox , oil units and generators to a turboset, according to the customer’s needs. The turbine skid and gearbox / oil unit are fully assembled in the workshop before being shipped to the site. Our proven installation and maintenance concept lowers maintenance cost by enabling easy access to the installed components, the turbine, gearbox, and generator.

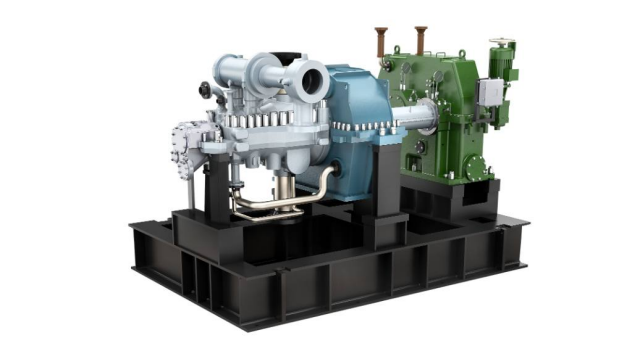

SST-300

Industrial steam turbine

The SST-300 is an optimal solution for a wide range of applications due to the implementation of the best technology combined with over 20 years of experience. In the last decade alone, this turbine has been installed in over 500 industrial and power applications by customers all over the world.

All components and auxiliaries including the lube oil system are mounted on a common base frame. The turbine can be configured with either an upward, downward or axial exhaust orientation depending on the layout of the plant.

The turbine can also accommodate multiple steam extraction / steam induction points as well. The compact design and simple layout of the turbine significantly reduce the cost and time associated with its construction, inspection and maintenance.

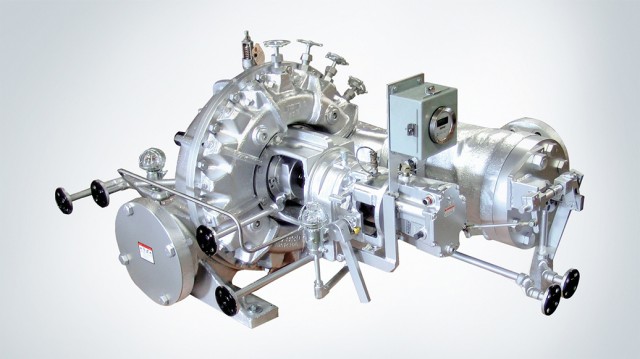

SST-200

Steam turbine for economical production of heat and power.

The SST-200 is a single casing steam turbine provided in a packaged, skid-mounted configuration. It represents a solution based on long experience with both mechanical and generator drives and is characterized by ease of installation, facilitated by the modular package. The tailor-made, flexible steam turbine exactly fits to the customer needs.

The Siemens SST-200 industrial steam turbine product line is based on the reaction blade technology. The turbine series follows a modular product philosophy, ensuring a high level of performance and reliability. The ability to combine standardized casing modules enable optimal design flexibility. This allows the turbine series to achieve high performance in combination with an optimal cost position.

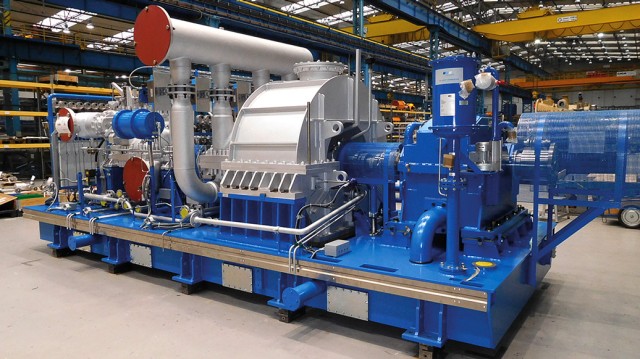

Dresser-Rand steam turbines from <10 kW to 25 MW

Whatever the requirements are, we provide either bare steam turbine drivers to OEMs, or we supply complete packages including gears, lube oil systems and controls. The Dresser-Rand steam turbines include standard single stage turbines for pump, fan & small compressor drives according to API 611 General Purpose (GP) standard, standard and engineered single stage turbines as generator drives for waste heat recovery applications and engineered single stage turbines and standard mulitstage turbines for applications according to API 611 (GP) or API 612 (Special Purpose – SP) standards

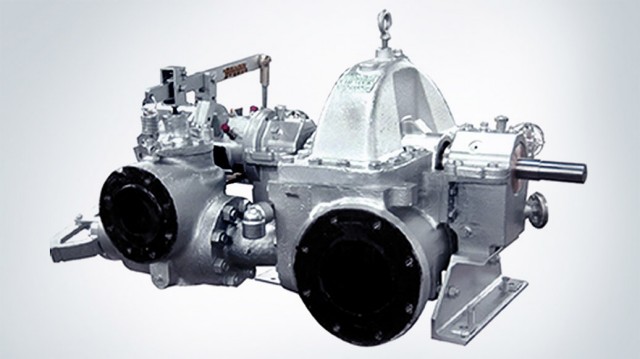

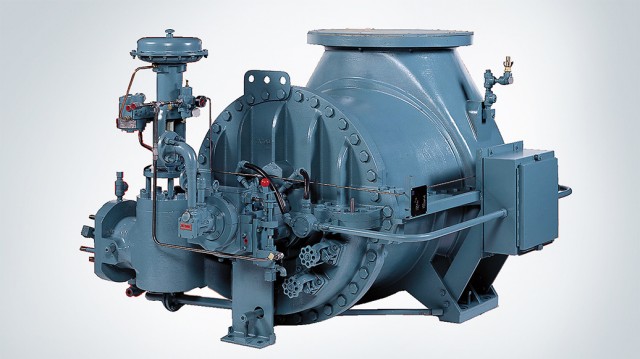

D-R SST 350 / 500 / 700

Standard single-stage steam turbine

- Rugged, versatile design

- Woodward TG Oil Relay NEMA Class A constant speed governor or electronic governor

- Horizontally split casing with centerline support

- Overspeed mechanical trip valve, separated from governor valve

- Carbon ring or labyrinth sealing glands

- Built-in, removable steam strainer

- API style blanket lagging / insulation (API applications)

- Oil ring with forced pressure lubrication or circulating oil cooling options

- Rolling element or tilting pad thrust bearings

- Broad range of controls and accessories available

- WORTHINGTON heritage (D-R SST 350 / 500)

D-R RLA

Standard single-stage steam turbine

- Rugged, versatile design

- Radially split casing with centerline support

- Woodward TG Oil Relay NEMA Class A constant speed governor

- API 611-compliant, positive-seating, mechanical overspeed trip valve

- Separate double seated governor valve

- Built-in removable steam strainer

- Removable carbon ring sealing glands

- API style blanket lagging / insulation (API applications)

- Oil ring lubricated

- Broad range of controls and accessories available

- COPPUS heritage

D-R RLVA

Standard single-stage steam turbine

- Rugged, versatile design

- Radially split casing

- Vertical shaft design with NEMA motor mounting flange & various ball thrust bearing configurations

- Woodward TG Oil Relay NEMA Class A constant speed governor

- API 611 compliant, positive seating, mechanical overspeed trip valve

D-R RLH

Standard single-stage steam turbine

- Rugged, versatile design

- Woodward TG Oil Relay NEMA Class A constant speed governor or electronic governor

- Horizontally split casing with centerline support

- API 611 compliant, positive seating, mechanical overspeed trip valve

- Separate double-seated governor valve

- Built-in removable steam strainer

- Carbon ring sealing glands

- API style blanket lagging / insulation (API applications)

- Carbon ring sealing glands

- Oil ring with forced pressure lubrication or circulating oil cooling options

- Broad range of controls and accessories available

- COPPUS heritage

D-R 2TA

Single-stage steam turbine

- Horizontally split casings

- Between-bearing design

- Multi-valve or single-valve inlet

- Solid or built-up rotor

- Carbon ring or labyrinth glands

- Electronic governor

- Electronic overspeed trip

- Trip and throttle valves

- API 611 & 612 compliance

D-R AVTTW / GTW

Single-stage steam turbine

- Integrally geared or direct drive overhung turbine design

- Available in horizontal or vertical configuration

- Axially split casing

- Multi-valve or single-valve inlet

- Derivative GTW frame used for compressor drives

- GTW overhung turbine design, direct drive

- Electronic governor

- Electronic overspeed trip

D-R C

Single-stage steam turbine

- Direct drive or integral gear operation

- Overhung design

- Multi-valve or single-valve inlet

- Marine classification approval

- Auto / quick start ability

D-R GAF

Standard multi-stage steam turbine

- Condensing or back pressure steam turbine

- Horizontal casing split

- Between-bearings

- Maximum 6 stages

- Single-valve inlet

- API 611 or 612 design

D-R U

Standard multi-stage steam turbine

- Unique above center line casing split allows removing the cover without disturbing the steam sealing areas, coupling and steam connections

- Condensing or back pressure

- Low cost applications

- Single-valve inlet

- Up to 10 stages

D-R R / RS

Standard multi-stage steam turbine

- Single-valve or multi-valve inlets

- Multiple uncontrolled bleeds

- Single automatic controlled extraction / induction

- Dual-acting, hydrodynamic, tilting pad thrust bearing

- Spherically seated or tilting pad-type journal bearings

- Interchangeable parts

- Standard assemblies and components

- API and non-API options

- Condensing or back pressure

- Up to 15 stages

D-R K

Standard multi-stage steam turbine

- Condensing or back pressure

- Low cost applications

- Single-valve inlet

- For a wide range of speeds throughout continuous operation

D-R B

Standard multi-stage steam turbine

- Condensing or back pressure

- Low cost applications

- Single-valve inlet

- For a wide range of speeds throughout continuous operation